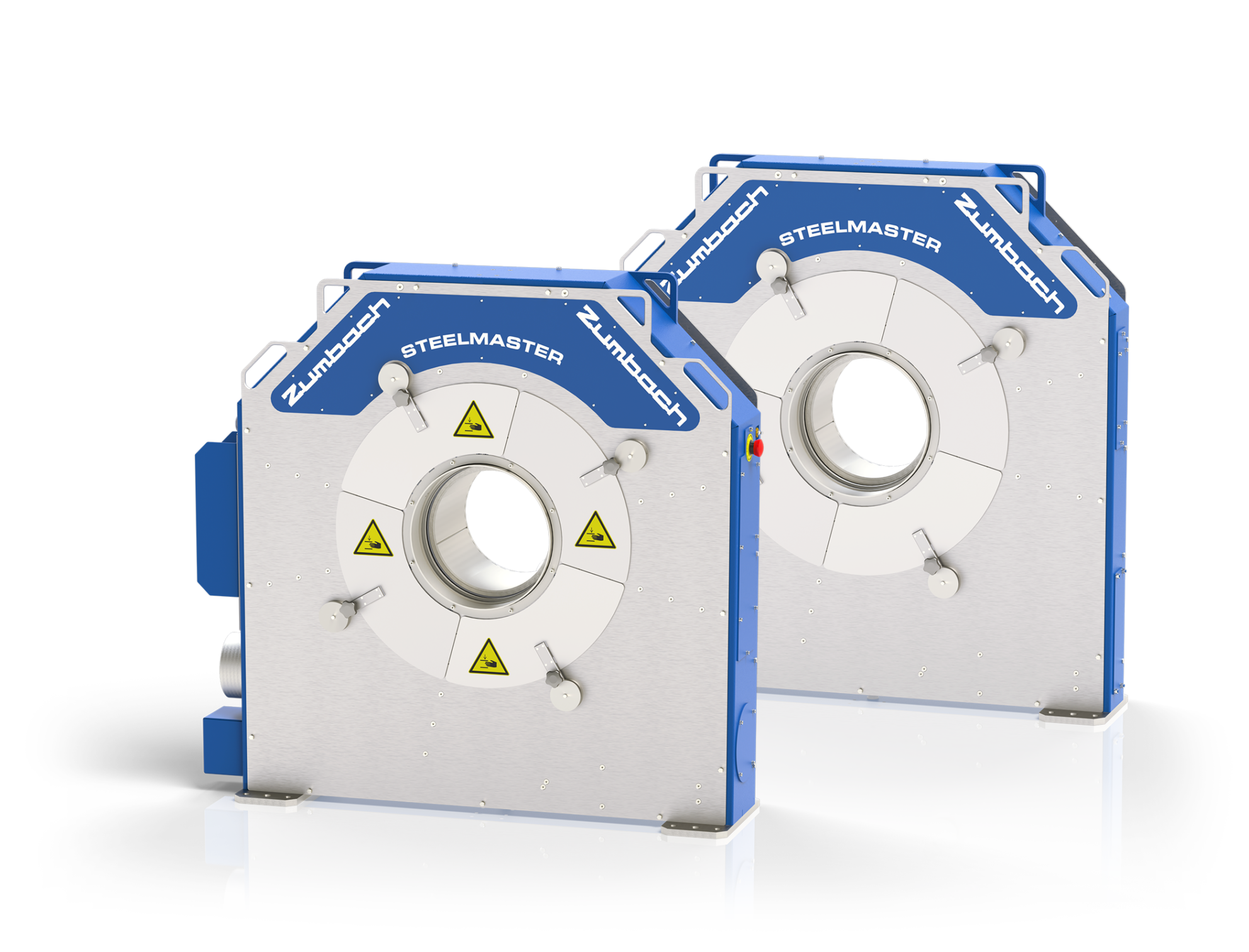

In the demanding world of hot steel production, precision is not a luxury. It’s a necessity! Whether producing billets, rods, pipes or wires, manufacturers must ensure dimensional accuracy to meet quality standards. To help steel manufacturers achieve the highest standards of production, Zumbach Electronic, a Swiss-based leader in industrial measurement technology, has created the STEELMASTER Dimension Measuring System. This system offers a suite of solutions tailored to different production environments, each designed to deliver high-speed, non-contact, real-time dimensional data and continuous quality control of the production line.

STEELMASTER is a family of laser-based, non-contact measuring systems engineered for inline monitoring of round and non-round products in hot and cold rolling mills. These systems are designed to detect dimensional deviations and shape irregularities with exceptional accuracy and speed. Utilizing a unique protection system, the STEELMASTER guarantees reliable measuring of products, even with temperatures up to 1200°C (2192°F), ensuring consistent performance even in the most demanding industrial environments. The STEELMASTER family includes two main product models:

- STEELMASTER SMS (Static Measuring System)

- STEELMASER SMR (Rotating Measuring System)

Each variant is optimized for specific production scenarios and measurement requirements.

STEELMASTER SMS: Static Precision for High-Speed Lines

Of the two systems, the SMS system is the most straightforward. It uses fixed laser heads to measure dimensions at extremely high speeds, up to 2,000 measurements per second per axis, with configurations supporting up to six axes providing up

to an exceptionally high 12,000 measurements per second. This results in a dense stream of measurement data, ideal for capturing fast or periodic variations in diameter of cross-section.

Typical applications where the SMS excels include hot rolling of billets, steel rods and pipes, cold processes like peeling, grinding and polishing, as well as continuous casting and NDT (non-destructive testing) lines.

The compact design of the SMS makes it easy to integrate, and requires minimal maintenance due to no contact or moving parts. Special versions can be offered for high-reflection surfaces and 3-roll mills. The SMS is ideal for short products and high-speed lines but is particularly effective when placed after intermediate rolling stands where it can detect issues like offset roll position, roll wear and dimensional error – periodic and continuous diameter variations that can compromise product quality.

STEELMASTER SMR: Rotating Excellence for Full Profile Coverage

The SMR system offers a significant advancement over the SMS. It features rotating laser measuring heads that scan the product in a continuous spiral pattern, delivering up to 6,000 measurements per second. This configuration ensures complete coverage of the diameter profile, making it ideal for final quality checks.

Typically utilized in the final measurement of steel wires and rods, the SMR is also used in the production of seamless pipes after the finishing die as an example, as well as in the detection of roundness, ovality, and polygonality of steel and metal products.

This system features a rotating main assembly equipped with 1 to 3 laser measuring axes, enabling a full profile to be captured with just a 60° rotation when using 3 heads. It incorporates “Calibrated Single Scan” (CSS) technology for high precision measurements, along with advanced software tools such as Enhanced Profile Measurement (EPM) and Full Profile Synthesis (FPS). Designed for efficiency, it operates without the need for compressed air and requires minimal maintenance.

The SMR system excels in environments where 360° coverage is essential. It detects radial dimension deviations, making it indispensable for final inspection stages where product integrity is critical.

Benefits of the STEELMASTER System

Across both variants, STEELMASTER Systems deliver high-speed, real-time measurement using non-contact laser technology that minimizes wear and maintenance. Its modular design allows integration into Multigauge setup for comprehensive monitoring, while early detection enhances process control, reduces scrap, and improves yield. Highly versatile, it adapts to diverse product shapes, sizes and production environments.

The STEELMASTER Dimension Measuring System from Zumbach Electronic represents the pinnacle of precision engineering in the steel and metal industry, providing a tailored solution that enhances quality control, reduces waste, and boosts operational efficiency. It’s the trusted choice for manufacturers who demand accuracy without compromise.