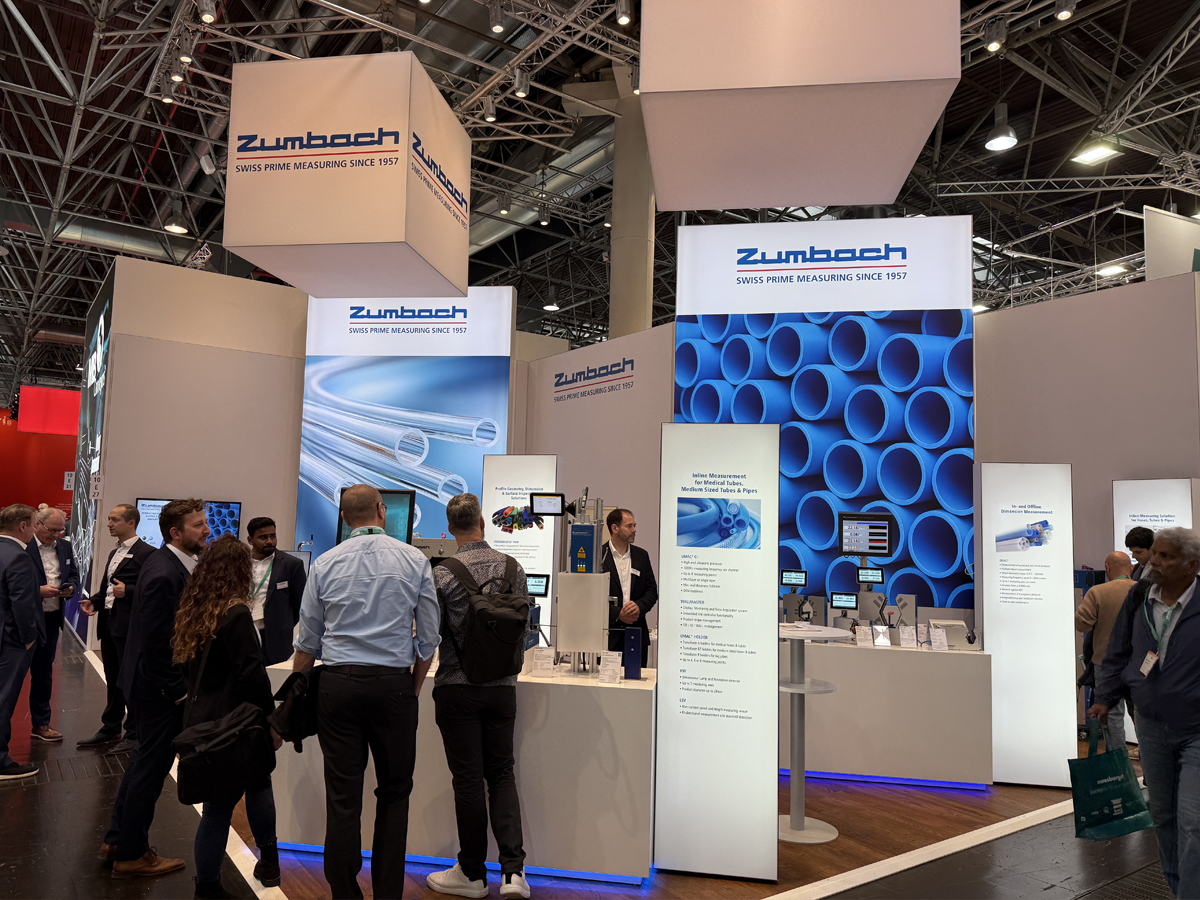

ZUMBACH ELECTRONIC proudly showcased its latest innovations in extrusion measurement technology at K 2025, the world’s leading trade fair for plastics and rubber which took place from 8th -15th October 2025 in Düsseldorf, Germany. Our presence at this year’s event reaffirmed our commitment to delivering cutting-edge solutions for the plastics and rubber industries.

At the heart of our exhibit was the UMAC® CI, a high-tech measured value processor designed for real-time wall thickness and eccentricity measurement in extrusion lines. This compact system integrates a powerful processor with a dedicated ultrasonic sensor, offering:

- High-speed precision measuring (up to 1000Hz per channel), ensuring stable accuracy even at high line speeds

- Advanced measuring algorithms for fast setup and seamless integration

- Universal connectivity supporting Profinet IO, Ethernet/IP, Ethernet TCP/IP, OPC UA, RS interfaces, and a USB/Ethernet service port for diagnostics, firmware and data transfer

- Flexible integration interfaces seamlessly with ODAC® laser sensors, KW lump and neck-down detectors and USYS® IPCe processors

- Embedded web server for intuitive visualisation and remote access through any standard internet browser, with no additional software required

- Reliable data acquisition for wall thickness, eccentricity, and other critical parameters

- Wide measuring range from 0.05mm ultra-thin wall thickness, adaptable from micro-tubes to heavy-wall pipes

The UMAC® CI is the result of decades of ultrasonic measurement experience, engineered to meet the evolving demands of modern extrusion environments.

Also debuting at K 2025 were our newly developed UMAC® ultrasonic transducer A-Holders, tailored for tubes and small pipes. These holders are designed to:

- Enable fast and accurate centering close to the extruder

- Support diameters from 0.2 mm to 28 mm (0.008 in. to 1.1 in.), and wall thickness from 0.05 mm to 12 mm (0.002 in. to 0.5 in.)

- 4 or 8 measurement points with optional horizontal/vertical configuration for flat or non-round products, such as busbar

- Dedicated USB service port enabling quick calibration, data logging, and synchronisation wit the UMAC® CI processor

- K & V versions configurable for open-trough or vacuum-tank setups, with height and side adjustment

- Durable, low-maintenance construction, stainless steel and POM body with integrated water rinsing to keep transducers bubble-free

- Plug-&-Play modularity, compatible with R, RZ and Z holders, extending the measurable range up to 400 mm diameter, plus customized solutions up to 1 m diameter

The new A Holders offer fast set-up, stable operation and minimal maintenance, helping manufacturers cut start-up waste and maintain tight tolerances.

In addition to our new developments, ZUMBACH presented its comprehensive portfolio of measurement systems, including: UMAC®; RAYEX® S; SIMAC®; ODAC® and the PROFILEMASTER® PMM with practical demonstrations outlining each product and solution’s features and benefits, as well as precision, efficiency and quality assurance across a wide range of extrusion processes.

Thank you to everyone who visited us at K 2025! We were thrilled to connect with industry professionals, partners, and innovators from around the globe. If you missed us at the show or would like more information about our solutions, complete the form below or contact your local ZUMBACH representative.